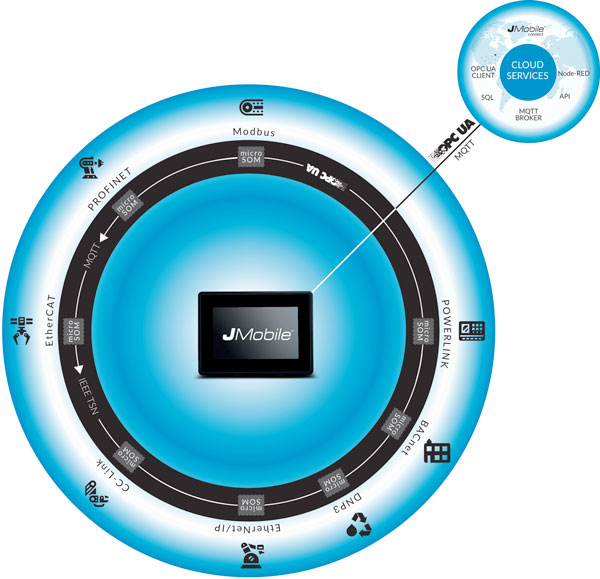

The eXware represents a prudent first step into the implementation of IIoT and Industry 4.0 compatibility. Acting as the central element in IIoT landscape the eXware can communicate between automation devices, cloud, fog and

applications.

This central role offers companies the chance to start at a uncomplicated level in IIoT and yet allows enormous future expansion into more complex aspects of Industry 4.0 as the workforce gains knowledge of this form of digital thread process and control.

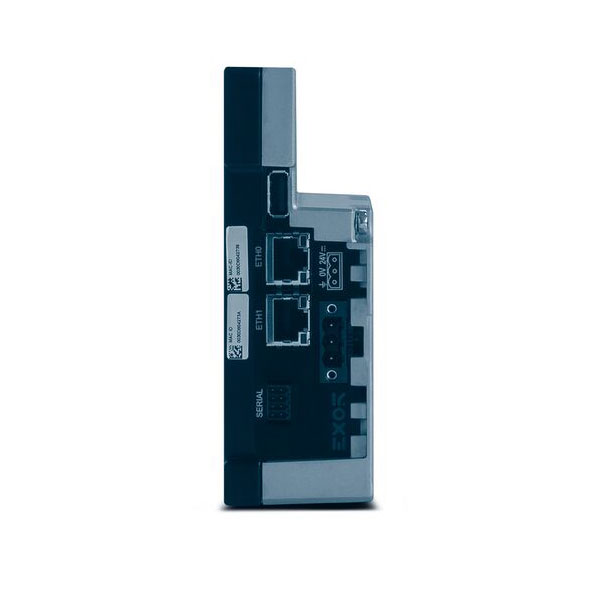

For maximum security the physical separation of the OT and IT networks with two ethernet ports has been provided and this avoids simultaneous attacks.

Secure HTTPS/TLS encrypted data transmissions with signed and packet transfer ensures against data theft and eavesdropping.

Seamless integration is achieved with the vast library of protocols that is common with JMobile software. Existing installations are easily employed and upgraded when necessary and very little programming skill is needed given the brilliant User Interface of JMobile.

Through use as a gateway, a powerful HMI, a PLC with CODESYS V3 or a secure router, the eXware facilitates data intensive and complex IIoT applications to be enabled.

- Plug and Forget integration into existing infrastructure

- Device data flow easily configured

- JMobile protocols and gateway functions

- JM4web HTML5 interface for web HMI

- CODESYS V3: supports network stacks and local I/O expandability

- Direct OPC UA communications

- JMcloud secure remote connectivity

- Plug-in module for system expansion

- 2 Ethernet ports for physical separation of the OT and IT networks

- Rugged and Beautiful all metal design

- Wide operating temperature range

- System settings by web browser

- Trusted and secure Linux-based operating system

- Secure HTTPS/TLS encrypted data transmissions

- Mobile Communication via PLCM09 2G/3G modem*

- Support for Geo-Localization*

- IoT data distribution via MQTT*

The eXware’s simple exterior hides an impressive performance beneath. With the sophisticated EXOR microSOM inside, multiple Ethernet ports and built for the highest levels of reliability, the eXware allows manufacturers to access the vast amounts of data already present on their shop floor without radically changing the factory set up.

Unfortunately over the past years the hype over Industry 4.0 has left many business owners and managers with little enthusiasm to seek and create new IIoT business models. Now that the technology is approaching the aspirations made, it is prudent and correct business management to capture data from the shop floor and store it securely. When the time comes that the new business model is ready, the data needed will be readily available.

The value in the data that exists already on the factory floor can easily be accessed using the eXware. This technology will allow companies to capture data in real time and drive improvements in productivity via more informed business decisions. This is the point of IIoT and these benefits can be accessed today and without any changes to the current factory floor.

The eXware offers you a safe foundation to launch your entire future IIoT Plan. Beginning your approach into Industry 4.0 by capturing the data that exists today should also not impede any further future IIoT implementation when your company is ready. As your workforce learns about the digital thread, the eXware, being a part of the X Platform of EXOR can scale in complexity and power to encompass the most complex IIoT implementation, including the development of entire IIoT ecosystems.

Using either a simple web browser or the JMobile client already available within the eXware, data acquired can be seen visually on the factory floor. Once the KPIs that matter to you are fixed a remarkable change occurs. This simple action lifts productivity instantly as operators first become aware that their performance is being monitored and thereafter take pride in their own improvement gains.

The EXOR microSOM inside the eXware, highly miniaturised, flexible and with a minimum 10 year product support, provides the unique high level of user experience. Working unseen this sophisticated technology permits true plug and forget capability. Able to quickly integrate into existing structures, it proves a powerful component of any production efficiency programmes.

Exor began developing the JMobile software in 2006 and spent nearly 4 years in close contact with 20 diverse customers to finally arrive at a minimal starting product. This trusting collaboration with the market has continued throughout the subsequent years and as a consequence has led to a unique software package.

JMcloud is a Secure Open VPN and SSL based solution that allows to remotely manage Industrial installation in an easy and yet extremely safe manner, avoiding expensive interventions on site. Simply by entering the credentials of the JMcloud portal, you have direct access to the system and you will be able to perform maintenance and upgrade, using the JMobile platform.

JM4web is the seamless connection between Industrial control applications and ubiquitous mobile devices such as smart phones and tablets. Developed some six years ago and subsequently continuously updated, it now provides the most comprehensive Pure Web Technology available, designed and maintained by Exor, a company with 45 years experience in control applications.